Activities

Ecofuel is a global operator in the international market which sells around 1 million tonnes per year of products worldwide (Europe, Americas, Asia) both directly from its production plants and through its own logistics terminals. Ecofuel's main product is high-octane alkyl ethers (bio-ETBE and bio-MTBE). In Italy they are produced at the Ravenna plant (about 200,000 tonnes/year), which was inaugurated in 1973 and has therefore reached the 50-year mark. It was the first plant ever built for the production of MTBE in the world.

Ecofuel holds interests in the following joint ventures:

- Saudi European Petrochemical Co. “Ibn Zahr”, which owns etherification plants with a capacity of about 1.5 million tonnes/year (it is the largest MTBE producer in the country) and polypropylene production plants with a capacity of about 1.1 million tonnes/year;

- Supermetanol C.A., which operates a methanol production plant in Venezuela with a capacity of about 700,000 tonnes/year.

Our strategy

How we promote sustainable growth and address challenges to achieve our goals.

High-octane alkyl ethers MTBE (Methyl Ter-Butyl Ether) and ETBE (Ethyl Ter-Butyl Ether)

Eni was the first company in the world to introduce an oxygenated compound like MTBE, an alkyl ether with high octane properties, into petrol in a systematic way, marketing it under the acronym “BD-1” (Black Dog 1) to recall the company's logo.

The technology for the production of MTBE was developed by Eni in its research laboratories and, through in-house technological know-how, it was successfully brought to industrial level by building the Ecofuel plant in the petrochemical plant in Ravenna. Ecofuel’s plant started operations in 1973 and it was the first example in the world of a plant for the production of MTBE. In 2023 it has reached the 50-year mark.

In the 1990s, in accordance with the changes in legislation associated with greater concern for the environment and the improvement of air quality, Ecofuel modified the Ravenna plant layout to allow it to produce the sustainable ether ETBE, which, by replacing methanol with ethanol, allows compounds from renewable sources, that do not require changes to fuel formulations or their distribution network, to be used as petrol components.

We work to improve air quality

Alkyl ethers are key components of petrol worldwide. By enabling the elimination of toxic lead-based compounds, they have made a major contribution to the ongoing process of improving the quality of petrol to meet increasingly strict emission standards. The addition of ethers results both in an improvement in the octane characteristics of petrol and in a reduction in emissions of CO, nitrogen oxides, particulate matter, volatile organic compounds and unburnt hydrocarbons.

In the near future, in order to further contribute to the decarbonization of transport, raw materials with an increasingly smaller carbon footprint will be used, such as second-generation ethanol obtained from non-food biomass (agri-business), renewable alcohols of non-organic origin (e-methanol) or from waste (bio- and low-carbon methanol), and hydrocarbon bases of organic origin.

Methanol

Methanol is the simplest of alcohols and has historically been used mainly to synthesise commonly used chemical compounds and finished products such as paints, adhesives, synthetic fibres, plastic and solvents.

In recent years, its use as an energy carrier has become increasingly important, as it is the liquid fuel with the lowest carbon content, which allows a reduction in harmful emissions (reduction of CO2 and nitrogen oxide emissions, elimination of sulphur oxides and particulate matter) and can be used as a replacement for traditional fossil fuels without any particular problems.

In some innovative fields, methanol has begun to be used as a fuel in power or heat generators (furnaces, burners, dryers, boilers), ship engines and Fuel Cells.

Ecofuel expects an increase in the use of sustainable methanol (bio-methanol, e-methanol and methanol from recycled carbon) in both the energy and chemical sectors.

The EU Directive 2009/28/EC (the Renewable Energy Sources or "RED” directive) concerning the promotion of the use of energy from renewable sources sets targets on energy consumption and defines sustainability criteria for biofuels and bioliquids including the reduction of greenhouse gas emissions. Since January 2012, compliance with sustainability criteria for biofuels has been mandatory in Italy, as provided for in Legislative Decree No. 28 of 3 March 2011 implementing the RED Directive.

Ecofuel has developed a Biofuel Sustainability Management System in accordance with the requirements of the RED Directive and has obtained the certification of sustainable products according to the ISCC (International Sustainability & Carbon Certification) standard and the National Certification Scheme, which are recognised by the European Commission. The Sustainability Management System applies to the production of bio-ETBE/bio-MTBE from bio-ethanol/bio-methanol and to marketing and storage activities and is designed to ensure the traceability of information associated with each product batch and the preservation of sustainability characteristics along the respective part of the supply chain.

The REACH Regulations

In conformity with European product safety regulations, Ecofuel products have been registered for the REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and CLP (Classification, Labelling, Packaging) regulations.

| REACH-registered substances | CAS |

|---|---|

| MTBE (Methyl Ter-Butyl Ether) | 1634-04-04 |

| ETBE (Ethyl Ter-Butyl Ether) | 637-92-3 |

| Methanol | 67-56-1 |

| Ethanol | 64-17-5 |

| Butane | 106-97-8 |

| Refined 2 (olefins C3-C5) | 68477-83-8 |

To implement and facilitate the transmission of information, Ecofuel has set up a dedicated communication channel: reach@ecofuel.eni.com.

Since it operates mainly through joint ventures with international partners, Ecofuel is a global player in the market for the chain of oxygenated compounds such as alcohols (Methanol) and high-octane alkyl ethers (ETBE/MTBE), which are then marketed worldwide (in Europe, the Americas and Asia).

In order to optimally monitor business scenarios of global interest, Ecofuel has founded and is involved in organisations, both national and international, that enable it to oversee the evolution of both market development processes (new product features or applications) and regulatory processes concerning quality, HSE and emission aspects.

Ecofuel is a member of the following organisations:

Our strategy

How we promote sustainable growth and address challenges to achieve our goals.

High-octane alkyl ethers MTBE (Methyl Ter-Butyl Ether) and ETBE (Ethyl Ter-Butyl Ether)

Eni was the first company in the world to introduce an oxygenated compound like MTBE, an alkyl ether with high octane properties, into petrol in a systematic way, marketing it under the acronym “BD-1” (Black Dog 1) to recall the company's logo.

The technology for the production of MTBE was developed by Eni in its research laboratories and, through in-house technological know-how, it was successfully brought to industrial level by building the Ecofuel plant in the petrochemical plant in Ravenna. Ecofuel’s plant started operations in 1973 and it was the first example in the world of a plant for the production of MTBE. In 2023 it has reached the 50-year mark.

In the 1990s, in accordance with the changes in legislation associated with greater concern for the environment and the improvement of air quality, Ecofuel modified the Ravenna plant layout to allow it to produce the sustainable ether ETBE, which, by replacing methanol with ethanol, allows compounds from renewable sources, that do not require changes to fuel formulations or their distribution network, to be used as petrol components.

We work to improve air quality

Alkyl ethers are key components of petrol worldwide. By enabling the elimination of toxic lead-based compounds, they have made a major contribution to the ongoing process of improving the quality of petrol to meet increasingly strict emission standards. The addition of ethers results both in an improvement in the octane characteristics of petrol and in a reduction in emissions of CO, nitrogen oxides, particulate matter, volatile organic compounds and unburnt hydrocarbons.

In the near future, in order to further contribute to the decarbonization of transport, raw materials with an increasingly smaller carbon footprint will be used, such as second-generation ethanol obtained from non-food biomass (agri-business), renewable alcohols of non-organic origin (e-methanol) or from waste (bio- and low-carbon methanol), and hydrocarbon bases of organic origin.

Methanol

Methanol is the simplest of alcohols and has historically been used mainly to synthesise commonly used chemical compounds and finished products such as paints, adhesives, synthetic fibres, plastic and solvents.

In recent years, its use as an energy carrier has become increasingly important, as it is the liquid fuel with the lowest carbon content, which allows a reduction in harmful emissions (reduction of CO2 and nitrogen oxide emissions, elimination of sulphur oxides and particulate matter) and can be used as a replacement for traditional fossil fuels without any particular problems.

In some innovative fields, methanol has begun to be used as a fuel in power or heat generators (furnaces, burners, dryers, boilers), ship engines and Fuel Cells.

Ecofuel expects an increase in the use of sustainable methanol (bio-methanol, e-methanol and methanol from recycled carbon) in both the energy and chemical sectors.

The EU Directive 2009/28/EC (the Renewable Energy Sources or "RED” directive) concerning the promotion of the use of energy from renewable sources sets targets on energy consumption and defines sustainability criteria for biofuels and bioliquids including the reduction of greenhouse gas emissions. Since January 2012, compliance with sustainability criteria for biofuels has been mandatory in Italy, as provided for in Legislative Decree No. 28 of 3 March 2011 implementing the RED Directive.

Ecofuel has developed a Biofuel Sustainability Management System in accordance with the requirements of the RED Directive and has obtained the certification of sustainable products according to the ISCC (International Sustainability & Carbon Certification) standard and the National Certification Scheme, which are recognised by the European Commission. The Sustainability Management System applies to the production of bio-ETBE/bio-MTBE from bio-ethanol/bio-methanol and to marketing and storage activities and is designed to ensure the traceability of information associated with each product batch and the preservation of sustainability characteristics along the respective part of the supply chain.

The REACH Regulations

In conformity with European product safety regulations, Ecofuel products have been registered for the REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and CLP (Classification, Labelling, Packaging) regulations.

| REACH-registered substances | CAS |

|---|---|

| MTBE (Methyl Ter-Butyl Ether) | 1634-04-04 |

| ETBE (Ethyl Ter-Butyl Ether) | 637-92-3 |

| Methanol | 67-56-1 |

| Ethanol | 64-17-5 |

| Butane | 106-97-8 |

| Refined 2 (olefins C3-C5) | 68477-83-8 |

To implement and facilitate the transmission of information, Ecofuel has set up a dedicated communication channel: reach@ecofuel.eni.com.

Since it operates mainly through joint ventures with international partners, Ecofuel is a global player in the market for the chain of oxygenated compounds such as alcohols (Methanol) and high-octane alkyl ethers (ETBE/MTBE), which are then marketed worldwide (in Europe, the Americas and Asia).

In order to optimally monitor business scenarios of global interest, Ecofuel has founded and is involved in organisations, both national and international, that enable it to oversee the evolution of both market development processes (new product features or applications) and regulatory processes concerning quality, HSE and emission aspects.

Ecofuel is a member of the following organisations:

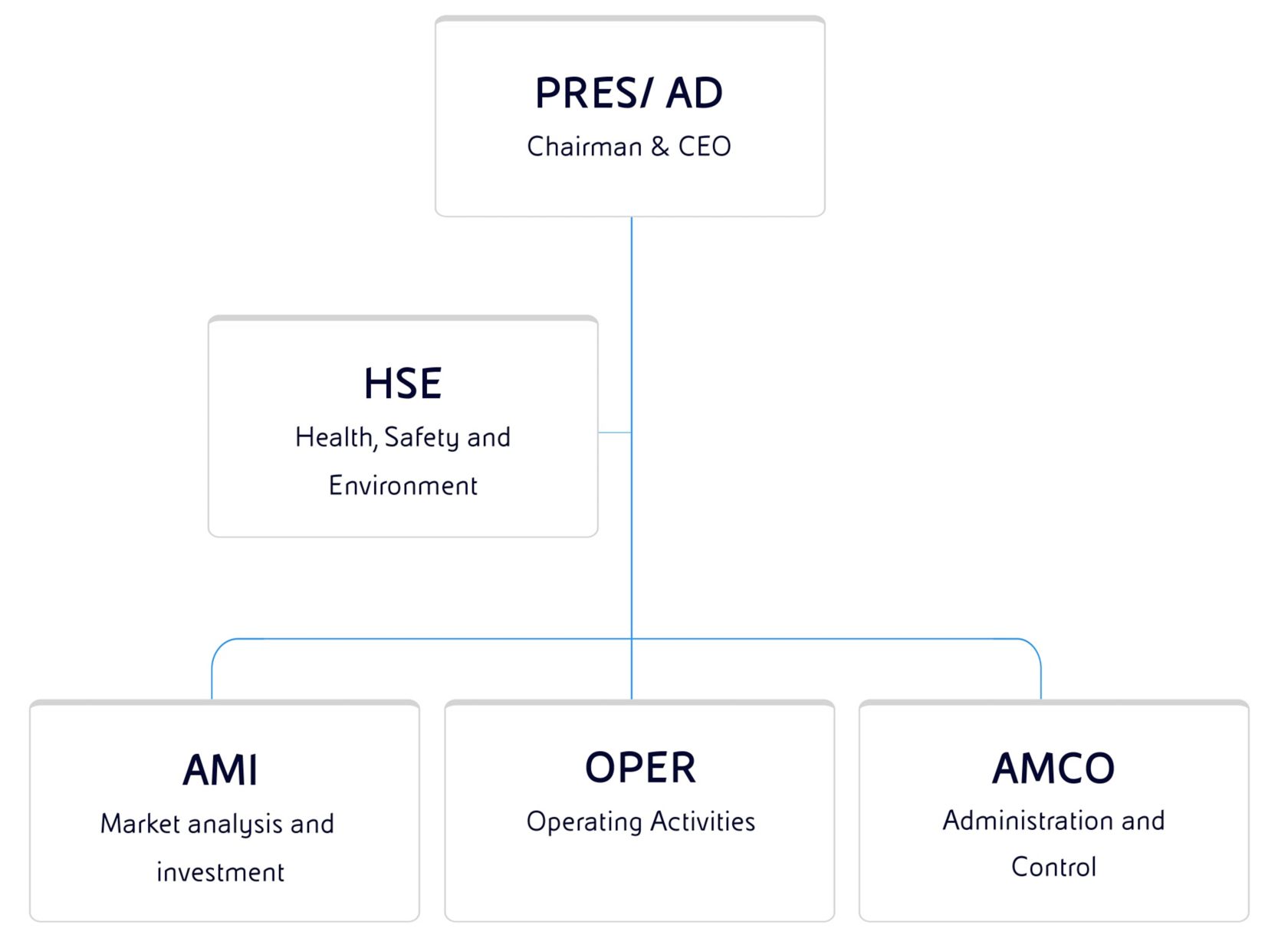

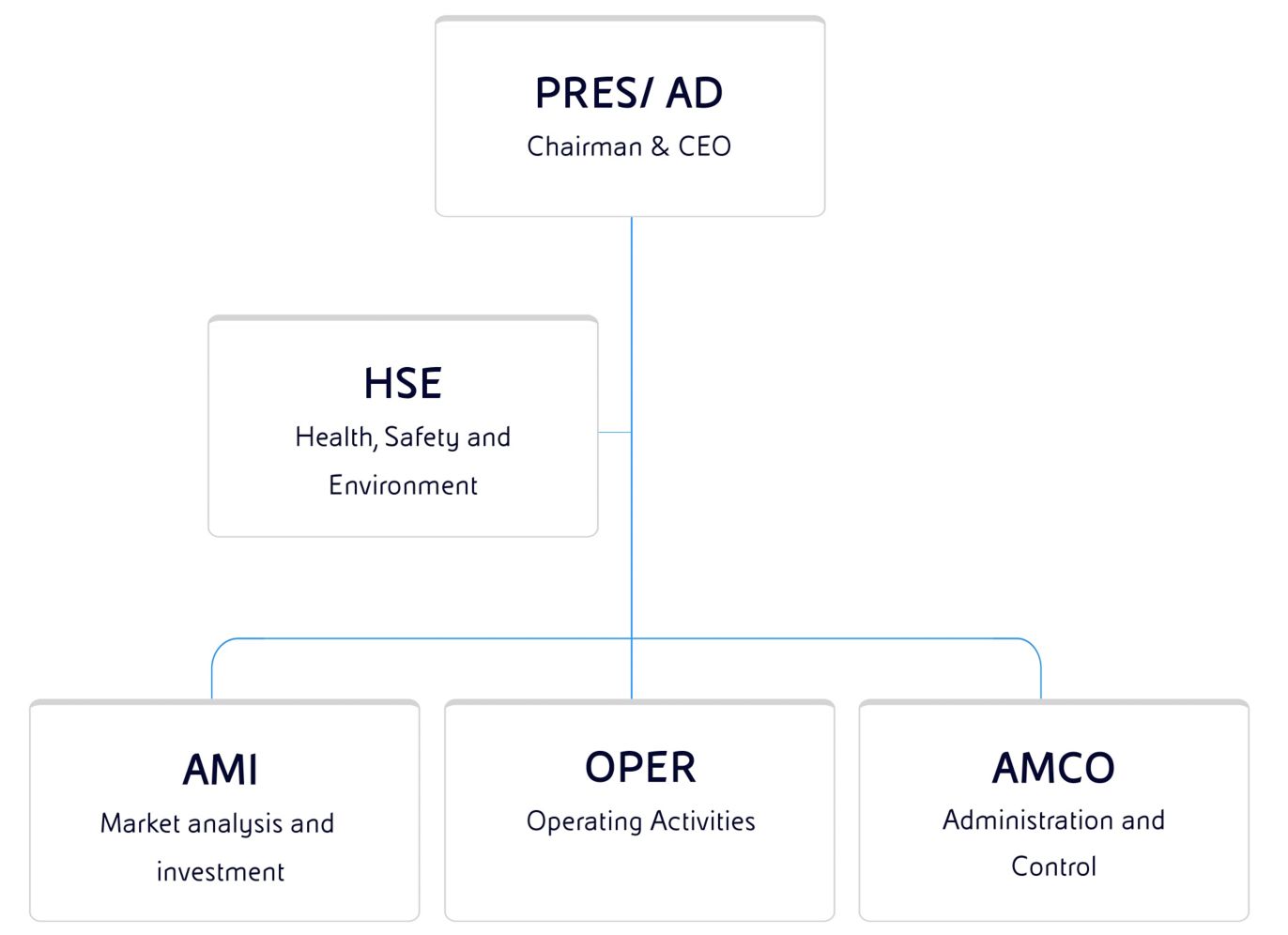

Our organisation

The corporate structure in detail, with names, roles and positions.

Board of Directors

The PWC SpA has been appointed to conduct the external auditing of the company for the 2019-2028 period.

Board of Statutory Auditors

Supervisory Body

The Supervisory Body appointed by the Board of Directors on 27 April 2023 is composed as follows:

- Chiara Dell’Isola

Milan Offices

Via Felice Maritano, 26

20097 San Donato Milanese

+39 02 520 56060

reach@ecofuel.eni.com